Powder coating is an excellent way to enhance your vehicle's aesthetic appeal and durability. Powder coating automotive components improve your automotive components' corrosion and wear resistance and provide your desired finish in a range of colors and styles.

At Powder Coat Art, we are the local specialist in automotive powder coating in Lebanon, TN. We can deliver precise, long-lasting powder coating services for everything from body panels to engine components. Our team relies on a proven powder coating process to ensure proper adhesion and a durable and appealing finish. Discover the benefits of powder coating services from Powder Coat Art in Lebanon, TN.

Applications of Automotive Powder Coating

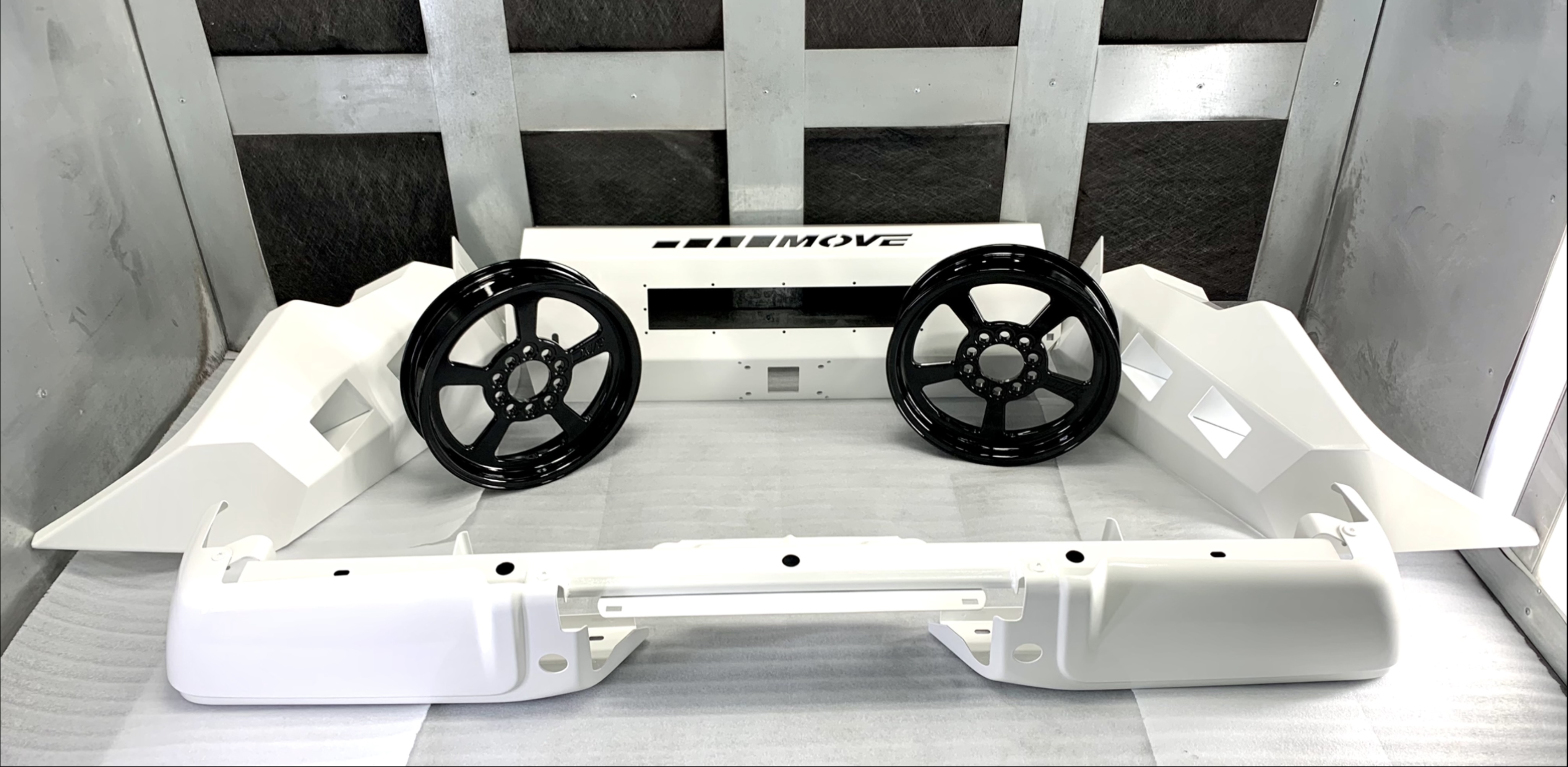

Automotive powder coating delivers additional durability and an appealing finish to body panels and components. Powder Coat Art can apply powder coat to the following components and body panels of your vehicle, providing durability, aesthetical appeal, and corrosion resistance:

- Luggage racks

- Bumpers

- Accent components

- Exterior trims

- Truck beds

- Hitches

- Crash bars

- Fenders and body panel

We can powder-coat your wheels, rims, and related components. Our wheel powder coating options include:

- Wheels

- Rims

- Axel housings

- Hubs

- Rotor hats

- Brake calipers

Vehicle frames and suspension components can also benefit from powder coating. We powder-coat the following frame and suspension components:

- Chassis frames

- Roll cages and bars

- Crash bars

- Leaf springs

- Coil springs

- Driveshafts

Powder-coating engine components deliver a personalized touch and corrosion resistance. We powder-coat the following engine and exhaust system components:

- Engine blocks

- Valve covers

- Engine components

- Exhaust components

- Automotive Powder Coating Process

While powder coating offers excellent adhesion compared to traditional paints and coatings, we follow a proven four-step process to ensure your powder-coated components achieve the desired surface finish:

- Surface Preparation: We remove the components that require powder coating to prepare them with sandblasting and cleaning. Our experts remove all rust, corrosion, dirt, and old paint before applying powder coating. This step is crucial for a successful result.

- Application Methods: The powder coating process consists of applying powder to the metal part through a high-quality electrostatic gun that clings the powder around the metal. Fluid bed coating is another powder coating method, where the fine powder is suspended in the air and the preheated component is dipped in a bath, melting the particles and fusing them to the surface.

- Curing Process: After the component is sprayed or dipped, a curing process exposes the component to high heat. This step melts the powder to coat your part evenly, plus the heat binds it tight and firm. We can use a specialized oven for baking the component at high temperatures or infrared (IR) radiation when the component is too thick to be thoroughly heated in an oven.

- Inspection and Quality Control: Once the component is cured, we thoroughly inspect the product for any defects, maintaining quality control throughout the powder coating process to rapidly deliver a durable and fully-cured product that will last decades.

Benefits of Automotive Powder Coating

Automotive powder coating delivers several advantages over traditional paint or coating techniques. The appearance is comparable to a professionally applied double-coating of paint and provides durable results that last years. Powder coating also delivers the following benefits:

- Enhanced durability to resist scratches, peeling, chips, and road wear—resistance to rust and corrosive liquids like brake fluid.

- Powder coating is environmentally friendly, reducing waste and volatile organic compound (VOC) emissions.

- We can customize the finish with various finishes and color options to meet your expectations.

- Powder coating delivers long-lasting results, reducing expenses on paint touch-ups and recoats.

Why Choose Powder Coating for Automotive Parts

One of the simplest ways to produce a durable and custom finish for automotive parts is to choose powder coating. Powder coating is an excellent finish that protects your metal auto parts and gives them a sleek design. If you’re wondering about powder coating automotive parts and how it works, you’ve come to the right place! Here’s the breakdown of what, why, and how behind auto parts powder coating.

What is Powder Coating?

Powder coating is a finish type for metal parts and objects that give a long-lasting and durable result. The powder coating process consists of applying powder to the metal part through a high-quality electrostatic gun that clings the powder around the metal. After it’s applied, the part is cured with heat. The curing process melts the powder to coat your part evenly, plus the heat binds it tight and firm. After this, the powder coating process is complete, and you have an excellent quality part that will last decades.

Why Powder Coating for Automotive Parts?

You’ve probably seen other finishing options out there for automotive parts, but powder coating is the best finish for auto parts. Why is that? First, automotive parts are exposed to intense heat, requiring a durable finish and technique. Auto parts also go through a lot of wear and tear, so the finish needs to be resistant to rust and other degradation. Powder coating is the answer for all of these needs because it holds up well to high heat and is very durable.

Beyond durability, powder coating also gives your auto parts a precise and quality finish. For example, if you are powder coating your vehicle’s wheels, you want it to be durable and look good. Powder coating provides the best of both worlds because it’s strong, precise, and customizable. There are many basic colors you can choose from and custom colors available to make your wheels personalized.

Often people want to repurpose old auto parts, like wheels, to bring new life into them. Powder coating works to help restore old auto wheels and make them look brand new. The reason for this is the intense preparation process that powder coating experts go through with the auto part before the actual powder application. Removing all of the rust, corrosion, dirt, and old paint before applying powder coating is crucial for a successful result. A good quality powder coating process works for both old and new automotive wheels.

How Long is the Process?

The last thing you need is to send off your automotive parts for powder coating, only to wait an unending amount of time for them to be returned. You read above that the powder coating process is relatively simple, making the delivery time efficient. In addition, it’s crucial to choose a partner that has the capability and experience to provide quick turnaround times.

At Powder Coat Art, we are experts in powder coating but also in quality and delivery times. Because of our location, it’s easier to get your automotive parts completed and sent back to you within an efficient time frame. In addition, our systems for completing quality powder coating and fast turnaround service make us the ideal partner for all of your automotive powder coating needs.

Transform Your Vehicle with Our Automotive Powder Coating Services

When you’re ready to transform your vehicle with automotive powder coating services, you can rely on Powder Coat Art. At Powder Coat Art, we are experts in powder coating, quality, and delivery times. Because of our location, it's easier to get your automotive parts completed and sent back to you within an efficient time frame. In addition, our systems for completing quality powder coating and fast turnaround service make us the ideal partner for all of your automotive powder coating needs. Contact us to speak with a team member about our powder coating services for your next project.